Railway Derails & Rerailers

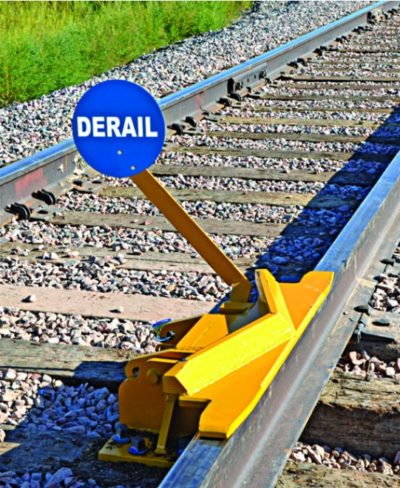

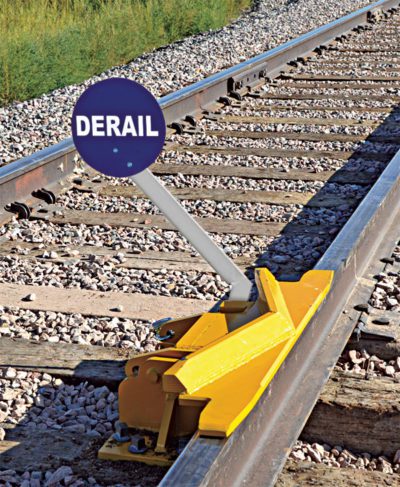

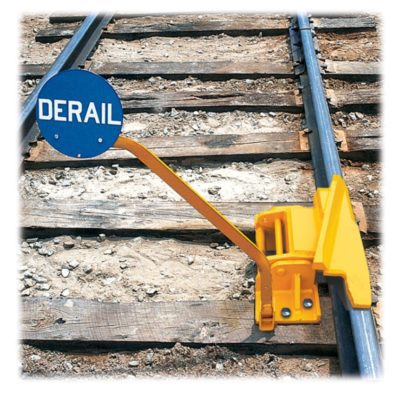

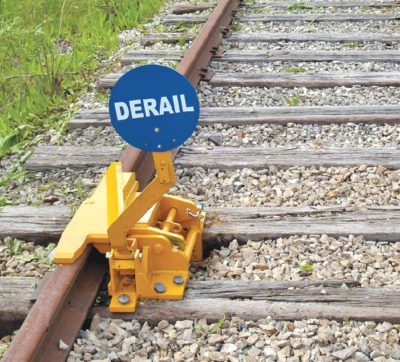

Hinged Railroad Derails

Since the founding of Aldon Company, Inc., Inc. in 1904, our product line has expanded, and our on-site engineers are ready to assist you to keep your rail yard running efficiently. View our hinged derail products below or contact our team today for assistance in purchasing.

Search

Showing all 12 resultsSorted by price: high to low

-

$2,480.16 Quick View

$2,480.16 Quick ViewTwo-Way Hinged Railroad Derail w/Pop-Up Sign Holder (For Locomotives)

Manufactured by Aldon®

4014-20

$2,480.16

-

$2,242.44 Quick View

$2,242.44 Quick ViewTwo-Way Hinged Railroad Derail w/Pop-Up Sign Holder (For Freight Cars)

Manufactured by Aldon®

4014-14

$2,242.44

-

$2,049.84 Quick View

$2,049.84 Quick ViewTwo-Way Hinged Railroad Derail w/Manual Sign Holder (For Locomotives)

Manufactured by Aldon®

4014-18

$2,049.84

-

$1,953.90 Quick View

$1,953.90 Quick ViewOne-Way “Right Throw” Hinged Derail w/Pop-Up Sign Holder

Manufactured by Aldon®

4014-12

$1,953.90

-

$1,953.90 Quick View

$1,953.90 Quick ViewOne-Way “Left Throw” Hinged Derail w/Pop-Up Sign Holder

Manufactured by Aldon®

4014-10

$1,953.90

-

$1,811.10 Quick View

$1,811.10 Quick ViewTwo-Way Hinged Railroad Derail w/Manual Sign Holder (For Freight Cars)

Manufactured by Aldon®

4014-03

$1,811.10

-

$1,766.64 Quick View

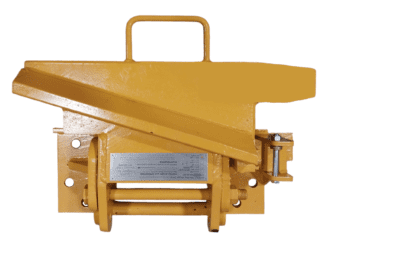

$1,766.64 Quick ViewSteel Tie Base Plate for Hinged Derails

Manufactured by Aldon®

4014-13

$1,766.64

-

$1,520.80 Quick View

$1,520.80 Quick ViewOne-Way “Right Throw” Hinged Derail w/Manual Lift Sign Holder

Manufactured by Aldon®

4014-02

$1,520.80

-

$1,520.80 Quick View

$1,520.80 Quick ViewOne-Way “Left Throw” Hinged Derail w/Manual Lift Sign Holder

Manufactured by Aldon®

4014-01

$1,520.80

-

$108.24 – $114.24 Quick View

$108.24 – $114.24 Quick ViewDerail Lifting Lever

Manufactured by Aldon®

DerailLever

$108.24 – $114.24

-

$91.15 Quick View

$91.15 Quick ViewDerail Padlock w/Chain And Lag Screw

Manufactured by Aldon®

4024-56

$91.15

-

$60.00 Quick View

$60.00 Quick ViewHandle For Hinged Derails

Manufactured by Aldon®

6196 & 6196A

$60.00

Frequently Asked Questions

What Are the Risks of Accidental Train Derailments?

Accidental train derailments can be damaging to equipment and track. They also pose a danger to rail workers, crew, passengers, and anyone within the surrounding area, and can potentially cause harmful effects to the environment.

Why Are Purposeful Derailments Used?

Purposeful derailments for railcars and locomotives using a derail device are utilized to prevent and control movement. Derails help prevent one car from rolling into another, unauthorized locomotive coupling to a stationary car and a loose car rolling out onto the mainline. OSHA, FRA, and DOT regulations require derail protection for all active rail sidings.

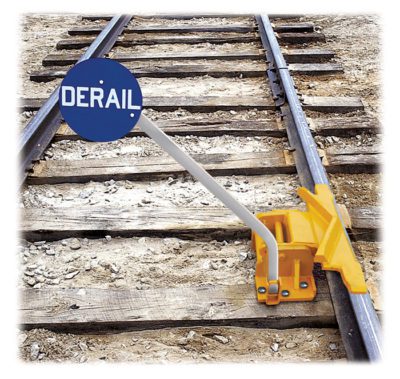

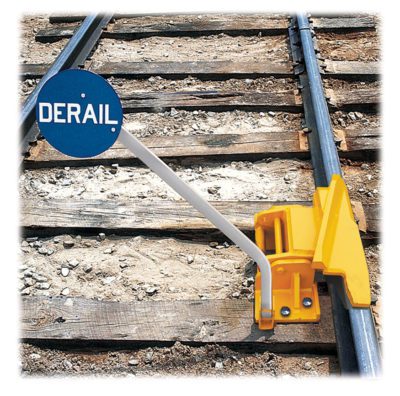

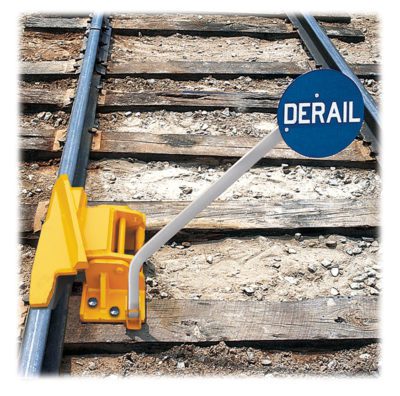

How Do Derails Work?

Derails work by lifting the flanges of the wheels and dropping them clear of the rails. At the same time the wheel on the other rail falls between the rails. The derailed wheels bite into the soft surface of the ties and ballast, then slide to a stop. Permanent and portable derails are both used to achieve this function.

What are Hinged Derails?

Hinged derails are spiked to two ties and can be flipped on or off rail by hand or by using a lifting lever. Hinged derails are designed to be used on exposed track (open to the ties), on wood, or steel ties. Aldon Company, Inc. can assist you in finding the correct model and placement location based on your needed application.