Loading Dock Safety Equipment

We specialize in providing high-quality loading dock safety equipment and accessories to protect workers, secure semi trucks, and prevent accidents during loading and unloading:

- Adjustable Height Trailer Stabilizer Jacks

- Walk-In Wheel Blocks with Flag & Handle

- Aluminum and Ductile Iron Wheel Chocks

- Rubber Wheel Blocks with Chain Attachments

- Trailer Flags & Wheel Blocks for Enhanced Visibility

Browse our full selection and invest in dependable equipment to maintain a safe and efficient loading dock environment.

Search

Product Filters

Showing all 19 resultsSorted by price: high to low

-

$725.00 Quick View

$725.00 Quick ViewAldon® Adjustable Height Trailer Stabilizer Jack

Manufactured by Aldon®

4013-13

$725.00

-

$370.00 Quick View

$370.00 Quick ViewWalk-In Wheel Block With Flag & Handle

Manufactured by Aldon®

4012-17

$370.00

-

$358.68 Quick View

$358.68 Quick ViewAldon® GUARDIAN® Trailer Stabilizer Aluminum

Manufactured by Aldon®

4013-15

$358.68

-

$220.90 Quick View

$220.90 Quick ViewAluminum Walk In Wheel Block

Manufactured by Aldon®

4012-11

$220.90

-

$179.98 Quick View

$179.98 Quick View(AL-107) Trailer Flag & Wheel Block “HWC” Style

Manufactured by Aldon®

4012-02

$179.98

-

$173.76 Quick View

$173.76 Quick ViewAL-96 Ductile Iron Block

Manufactured by Aldon®

4012-04

$173.76

-

$163.30 Quick View

$163.30 Quick ViewHWC Wheel Block & Handle

Manufactured by Aldon®

4012-16

$163.30

-

$158.57 Quick View

$158.57 Quick ViewTrailer Flag & Wheel Block “LWC” Style

Manufactured by Aldon®

4012-13

$158.57

-

$153.48 Quick View

RWC Rubber Block Joined By 5 Ft of Chain

Manufactured by Aldon®

4012-05KIT

$153.48

-

$109.19 Quick View

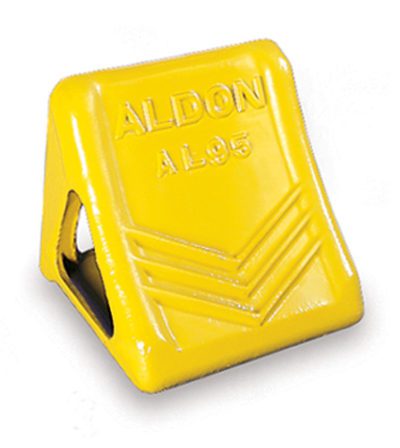

$109.19 Quick ViewAL-95 Ductile Iron Block

Manufactured by Aldon®

4012-06

$109.19

-

$88.61 Quick View

$88.61 Quick ViewLanding Leg Support Pad (Dolly Pad)

Manufactured by Aldon®

4024-04

$88.61

-

$82.58 Quick View

$82.58 Quick ViewRWC Rubber Block

Manufactured by Aldon®

4012-05

$82.58

-

$77.89 Quick View

$77.89 Quick ViewHWC Aluminum Wheel Block

Manufactured by Aldon®

4012-03

$77.89

-

$57.31 Quick View

$57.31 Quick ViewHWC/LWC Wheel Block Wall Pocket

Manufactured by Aldon®

4012-15

$57.31

-

$52.13 Quick View

$52.13 Quick ViewLWC Aluminum Wheel Block

Manufactured by Aldon®

4012-01

$52.13

-

$46.34 Quick View

$46.34 Quick ViewWheel Chock Bracket

Manufactured by Aldon®

4012-14

$46.34

-

$34.00 Quick View

$34.00 Quick ViewWinch Pry Bar For Trucks

4120-02

$34.00

-

$18.69 Quick View

$18.69 Quick ViewBrass Padlock

6295

$18.69

-

$4.00 Quick View

$4.00 Quick ViewQuick Link Chain

Manufactured by Aldon®

4012-07

$4.00

Frequently Asked Questions

What are the OSHA requirements for loading docks?

OSHA requires loading docks to maintain a safe environment by preventing accidents and injuries. This includes using proper lighting, ensuring stable equipment like dock plates and wheel chocks, and implementing fall protection on elevated docks. Regular maintenance and employee training are also critical for compliance. Learn More

What type of loading dock supplies and accessories do you offer?

We offer a wide range of loading dock supplies and accessories, including:

- Adjustable Height Trailer Stabilizer Jacks

- Wheel Chocks (rubber, aluminum, and ductile iron options)

- Walk-In Wheel Blocks with Flag & Handle

- Trailer Flags for better visibility during operations

- Rubber Blocks with Chain Attachments

What is the most common loading dock?

The most common loading dock is the flush dock. Flush docks align with the building wall, allowing trucks to back up directly and providing easy access for loading and unloading. They are widely used due to their space efficiency and versatile design.

Why are trailer restraints important for loading docks?

Trailer restraints are essential for preventing trailer movement during loading and unloading. They help avoid accidents caused by trailer creep or premature departures, ensuring the safety of workers and the stability of heavy equipment.

What is the difference between a rubber wheel chock and an aluminum wheel chock?

Rubber wheel chocks are durable, weather-resistant, and provide excellent grip on various surfaces, making them ideal for heavy equipment. Aluminum wheel chocks are lightweight, long-lasting, and often used for applications requiring portability without sacrificing durability.